An Inside Look At AiM Belt Temp Gauges

Words by: Kyle Callen

Photos: Brandon Bunch

In the UTV world drive belts are still life, in the turbo category at least, so we’re still stuck dealing with them. Luckily there is quite a lot to learn and know about belts and clutching to help them live as long as possible. Most belts see a pretty rough life with crazy heat cycles, dirt, debris, and punishingly bad drivers. It is amazing that they live for as long as they do. The most common cause of death for a belt is heat. But, from the factory most UTVs don’t have a way to monitor belt temp, even though it is every bit as crucial as engine temp. There are several belt temp gauges on the market, but when it comes to monitoring this crucial vital sign, a quality sensor and gauge will pay for itself.

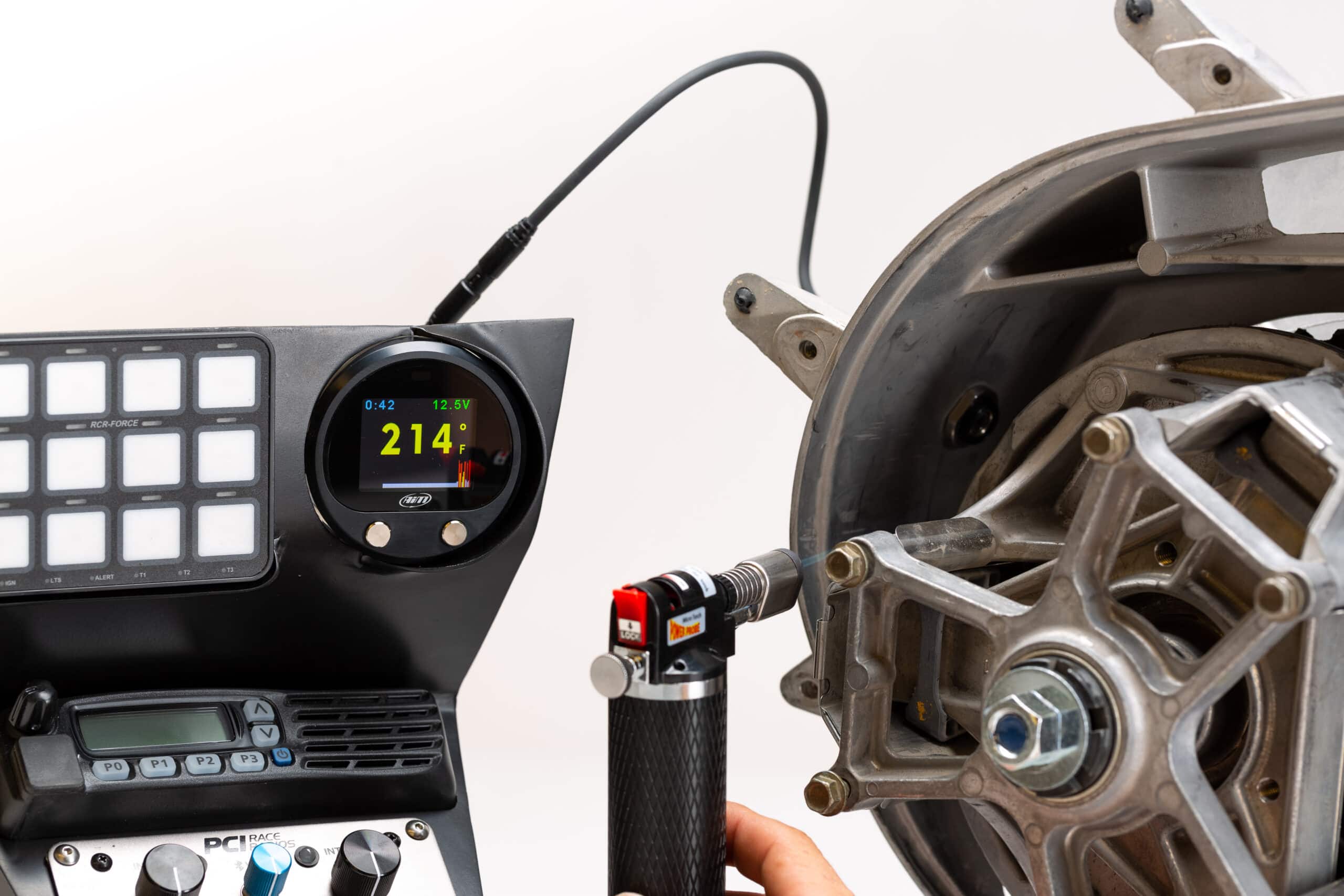

AiM has gone shoulder deep in their efforts to support the powersports industry, bringing years of data logging and monitoring experience to our sport. They are building full blown race car parts and making them affordable to the average recreational rider. We got our hands on one of their Infrared Belt Temperature Systems and from the packaging to the wiring, the quality is the best we have seen.

A simple menu system navigated by two buttons allows you to set operating ranges for the ‘Warning’ and ‘Alarm’ functions.

The key to making a belt temp gauge work properly is the correct mounting of the infrared sensor. Before installing the system on our test stand, I called and chatted with AiM. They recommend that the sensor be mounted vertically, looking down on the center of the belt in between the primary and secondary clutches. This will help keep debris and contaminants from impacting or sticking to the sensor and ensure an accurate reading. In our Polaris RZR Turbo S application, this was not an option due to the inner clutch housing design.

They said try and mount it as vertically as possible, but anywhere will really work, as long as it’s perpendicular to, and aligned with the centerline of the belt. The sensor works by simply reading infrared radiation, which ‘has a wavelength from about 800 nanometers to 1 millimeter, and is emitted particularly by heated objects’, according to the internet. By measuring that wavelength, or distance between wave peaks and troughs, of this invisible radiation being emitted by the hot belt, the sensor, processor, and display together will let you know whether or not it’s time to panic. Basic handheld infrared thermometers work in the same manner—you know, the things people like to point at your face everywhere you go these days…

The advantage to the AiM gauge is you don’t have to watch your temps with eagle eyes like some of the others out there. The easy to use menu system allows you to go in and change the ‘Warning’ and ‘Alarm’ settings. Yellow ‘Warning’ numbers indicates that the belt is starting to creep up on the hot zone and you may need to back out of the throttle. As the temp increases, the numbers will change to red and the gauge will ‘Alarm’ with a flashing red light. At this point, you have two options: back out of the throttle or change the belt when it grenades. These warning light ranges can be adjusted for your operating range preferences. Erroring on the side of caution and keeping the warnings at a slightly lower temp will ensure that when you glance at the gauge, you will catch the creeping temp before it is too late.

When in the safe range, the numbers display white… As they climb into the danger zone, they become first yellow, and then red as catastrophe nears.

Proper maintenance of your belt and clutches is the best way to ensure a long healthy belt life in the shop. But while you are on the trail, the dunes, or the race course, the AiM Infrared Belt Temp System will help you keep an eye on what is happening behind the clutch cover, keeping you moving faster for longer periods of time.